- Why FOCUS for USP <71> Sterility Testing?

- Conventional sterility testing

FOCUS Laboratories can test product sterility through USP <71> tests. All samples are prepared and plated in ISO 5 hoods in ISO 7 clean rooms, to eliminate laboratory contamination. We can test sterile product in one day via a rapid SCAN RDI method and are proud to produce accurate, on time and cost-effective results.

Call us at 610-866-7272 for a free quote.

Sterile drug manufacturers and compounders assure product sterility through rigorous aseptic processing controls and validation, which include proper training, gowning, HVAC and equipment design, environmental monitoring, media fill verification and other means. End product testing is only one part of this strategy – absence of organism presence in this test does not mean presence of organism absence in the entire lot. A very small portion of the batch is subjected to sterility testing. Below is a minimum number of parenteral articles to be tested based on batch size, according to USP 40:

Number of Items in the Batch |

Minimum Number of Items to be Tested for Each Medium: |

|---|---|

< 100 containers |

10% or 4 containers, whichever is greater |

101 – 500 containers |

10 containers |

>500 containers |

2% or 20 containers, whichever is less |

Product is typically filtered through a 0.45 micron filter, and after the filter is washed with sterile diluent it is placed in either an aerobic medium (Tryptic Soy Broth) or an anaerobic medium (Fluid Thioglycolate Medium). The filter and the media are incubated at appropriate temperatures for two weeks.

If the product can’t be filtered, it may be directly inoculated into culture media. The volume of the product should be less than 10% of the volume of the medium.

At intervals during the incubation period and at its conclusion, the media are examined for evidence of microbial growth. Evidence may include turbidity, pellicle formation or other microbial indicators. Growth is confirmed by streaking to agar and the isolates are identified. Identification of microbial contaminants may be useful in identifying how the product failed.

FOCUS Laboratories partner Atlas Analytical test product in ISO 5 hoods housed in ISO 7 clean rooms. Sterility specialists gown completely in sterile garments with no skin showing.

Sterility Testing must be validated for the product being tested, to demonstrate that product will not inhibit growth of microbes in the sterility media. Method Suitability is demonstrated by performing sterility test and then inoculating media and filter or media and product with <100 cfu of select test species.

Media |

Test Species |

Incubation Temp. |

|---|---|---|

Tryptic Soy Broth |

Bacillus subtilis |

20 – 25°C |

Fluid Thioglycolate Medium |

Pseudomonas aeruginosa |

30 - 35°C |

Growth of microbes must be evident in the product broth solutions within 5 days.

Test Requirements:

Sample quantity is based on USP Tables for batch size and unit dose size. Turn around time is 3 weeks.

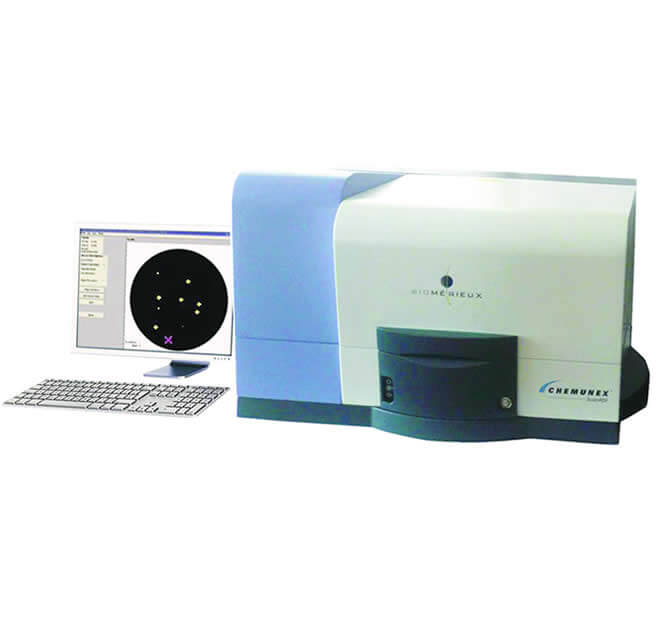

FOCUS Laboratories partner Atlas Analytical can test sterile product in one day via a rapid SCAN RDI method. This method confirms sterility of product within one day, and is not dependent on slow growth procedures but chemiluminescent technology.

Essentially, product is filtered through a 0.4 micron membrane, in the quantities described by USP <71>. The filter is then subjected to a series of dye steps, and is scanned by laser.

The "viability substrate" component of the labeling solution enters the microorganism through the cell membrane. Living cells cleave the non-fluorescent viability substrate by an enzymatic reaction, releasing fluorescent particles (free fluorochrome) within the cell. The cell's membrane holds the light-emitting fluorochrome within the cell and allows it to be detected by the SCANRDI's laser. Nonliving cells are not metabolically active and not labeled.

The SCANRDI's laser scans the entire membrane in less than three minutes and immediately displays the total number of living cells fixed to the membrane. The scan map and microscope attachment allow for quick visual confirmation of results by trained and qualified microbiologists.

The entire system has been validated, and each formulation is qualified through method suitability testing.

More information can be found at equipment manufacturer’s website by Clicking Here.

Test Requirements:

Sample quantity is defined by USP <71>, and turn around time can be as short as 1 day.